Shanlong's products have been upgraded again!

In this beautiful May, the Shanlong injection molding machine's robotic arm drive control integrated machine has been completely upgraded, with further optimization of product performance and a better customer experience!

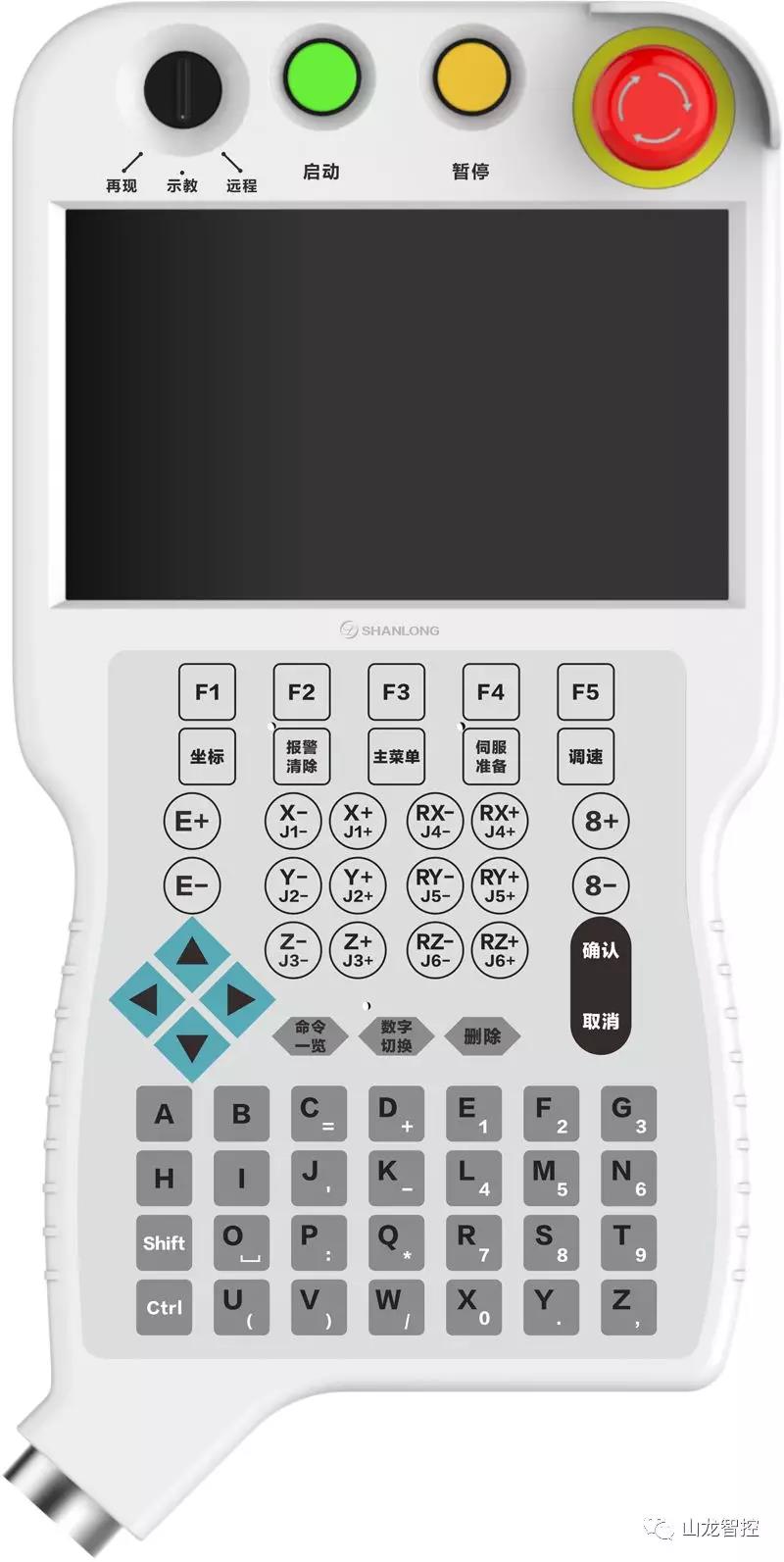

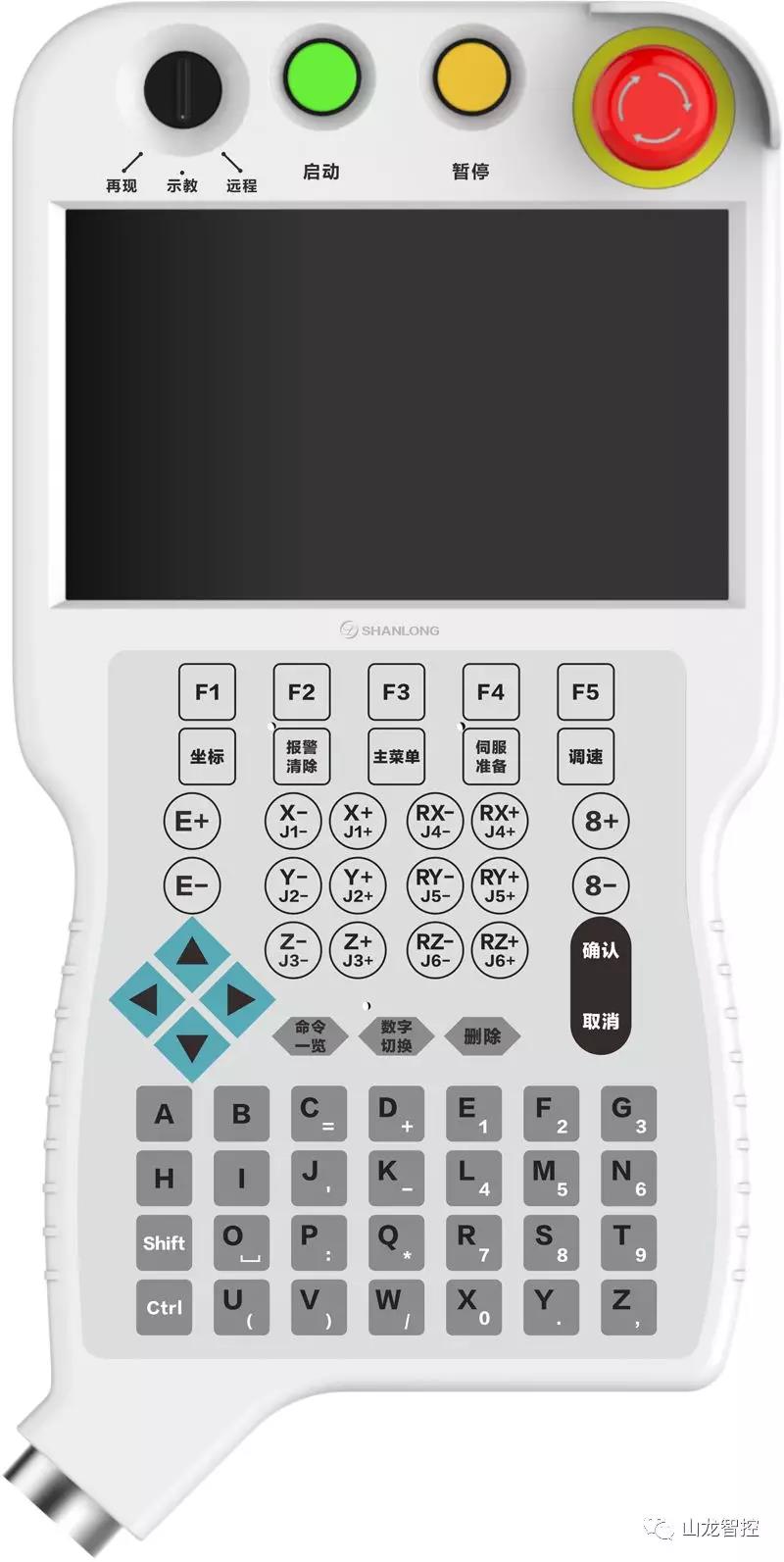

New teaching pendant

Dignified and elegant, elegant and mature

Old teaching pendant

A graceful and graceful figure

New upgrade

1. The screen is even larger

Upgrading from a 7-inch screen to an 8-inch screen, providing customers with a better visual experience

2. More complete information

Add running status LED and other prompts to provide a more intuitive understanding of the current status

3. More efficient

Increase handwheel control to improve teaching efficiency

4. You can be lazy for a while

Reduce buttons to better align with industry operating characteristics

The upgrade of the teaching pendant has greatly improved its appearance, performance, and operation. The integrated drive control machine CD6030 is used in conjunction with the upgraded teaching pendant, making the product more convenient and powerful in use.

Drive Control Integrated Machine CD6030

D6030 is a combination of years of control technology and servo drive technology by Shanlong. It adopts an X86+DSP architecture platform, with excellent performance of high resolution, high response, and high reliability. It adopts a self-developed secondary development environment to achieve three-axis linkage interpolation and logical control, especially suitable for injection molding robots, stamping robots, truss robots, and so on.

Compared to traditional products, CD6030 has the following advantages:

Rich IO resources and support for bus expansion, with configurable IO definitions.

Breakpoint memory function. When encountering a pause during operation, the current program can be continued after the start to improve production efficiency.

Multiple protections such as motion axis fault detection, jib outer membrane safety function, and trial operation rule detection ensure production safety.

Chinese teaching programming is easy to learn and operate, and there are prompts for errors in deletion and combination during programming, ensuring the accuracy of the program.

Small size, less wiring, support for servo/system parameter import and export, making installation and debugging more convenient.

Support RS-485 and RS-232 communication, which is more conducive to increasing the connection of instruments such as vision and sensors.